SOLAR SOLUTION

Solar has entered the mainstream as the world’s cheapest energy source, leaving many people wondering how solar PV can be so efficient and inexpensive while still providing “green” energy. Answering that question means understanding how solar energy work, how solar panels are manufactured and what the parts of a solar panel are. Most panels available on the market are made of monocrystalline, polycrystalline, or thin film (“amorphous”) silicon. In this article, we’ll explain the different ways solar cells are made and what parts are required to manufacture a solar panel.

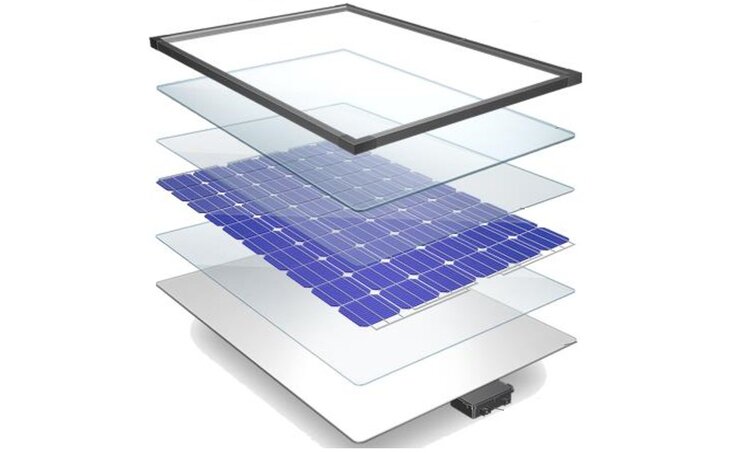

Six Main Components Of A Solar Panel

-

Solar photovoltaic cells

-

Toughened Glass – 3 to 3.5mm thick

-

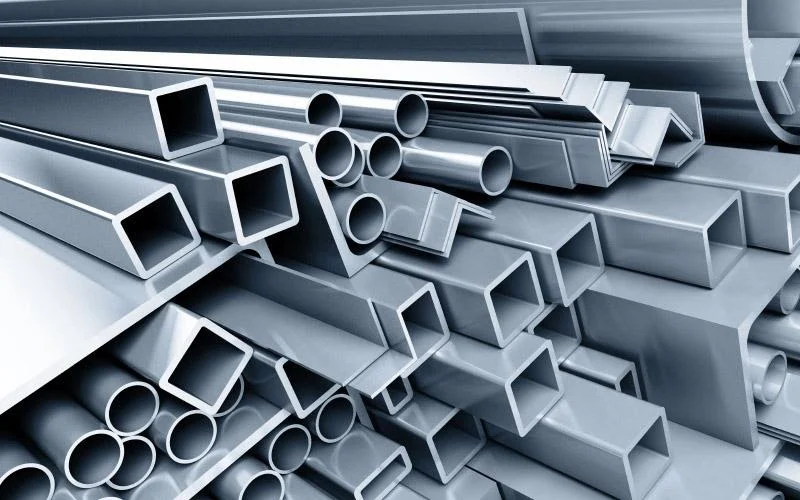

Extruded Aluminium frame

-

Encapsulation – EVA film layers

-

Polymer rear back-sheet

-

Junction box – diodes and connectors

Many well known solar panel manufacturers are ‘vertically integrated’ which means the one company supplies and manufactures all the main components including the silicon ingots and wafers used to make the solar PV cells. However many panel manufacturers assemble solar panels using externally sourced parts including cells, polymer back sheet and encapsulation EVA material. These manufacturers can be more selective about which components they chose but they do not always have control over the quality of the products so they should be sure they use the best suppliers available.

Project Details

- Client : Dream Club

- Service : SPECIALTY METAL

- :